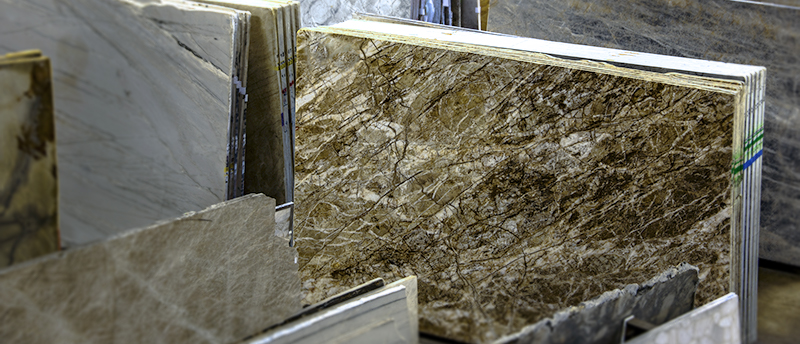

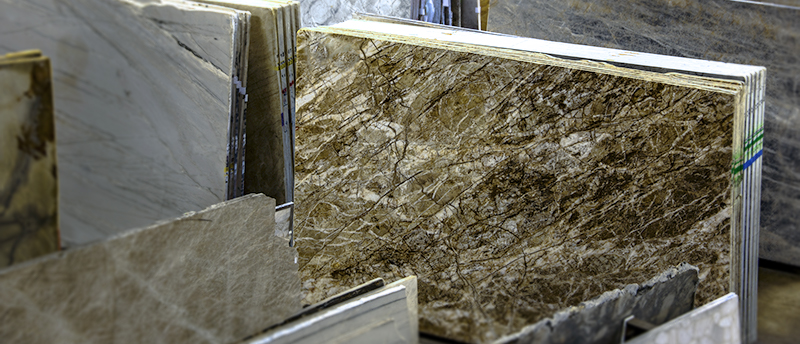

The past few years have brought awareness to an old occupational health risk appearing in a modern industry. Workers who manipulate "engineered stone" countertops are falling ill with a disease known as silicosis. Silicosis is a potentially deadly disease that takes the lives of 100 American workers each year. As concern and awareness grow around the safety of handling "engineered stone," many workers who frequently work with materials containing silica are filing silica dust exposure lawsuits.

The past few years have brought awareness to an old occupational health risk appearing in a modern industry. Workers who manipulate "engineered stone" countertops are falling ill with a disease known as silicosis. Silicosis is a potentially deadly disease that takes the lives of 100 American workers each year. As concern and awareness grow around the safety of handling "engineered stone," many workers who frequently work with materials containing silica are filing silica dust exposure lawsuits.

What Is Silica?

Silica is a mineral found in soil, sand, various types of rocks, and other materials commonly found at construction sites. Silica is used in many manufacturing and construction industries. Inhaling silica dust can prove to be very dangerous. Airborne crystalline silica -- fine, breathable silica dust - is a human carcinogen linked to lung cancer and several other serious diseases.

Industries Affected by Silica Exposure

Because silica is found in many natural stones and mineral ores, it is common in many manufacturing industries and on construction sites. Those who know about silica dust exposure typically equate it with industries that work with stone materials, sands or soil. However, occupational risk isn't limited to those working with genuine or artificial stone. Workers may need to be careful if they work with drywall, grout, paint containing silica, roofing materials, paving materials, or tile.

If a material containing crystalline silica is cut, broken, crushed, drilled into, polished or ground down, the action could release toxic silica dust or fibers. Without proper safety measures in place, this silica dust can affect the health of anyone in the general vicinity of the product.

Due to the nature of the material and how exposure occurs, silica is often compared with another well-known environmental carcinogen, asbestos.

Some industries that are high-risk for silica dust exposure include:

- Mining

- Abrasive blasting

- Construction (e.g. highways, bridges, buildings)

- Cement, brick or asphalt manufacturing

- Masonry

- Concrete work

- Foundry industries

- Demolition

- "Engineered stone" manufacturing

Silica Dust Health Hazards

The most common health complication associated with silica exposure is silicosis -- a devastating lung disease. However, having silica in the lungs can also lead to the development of severe health side effects and silica-related diseases such as tuberculosis, silica lung cancer, chronic obstructive pulmonary disease (COPD), kidney disease, chronic bronchitis, and multiple silica cancers. Even short-term exposure to silica dust can result in serious health issues.

Silica Exposure Screening

If you've been exposed to raw silica powder, it is important to see your doctor about screening options to determine if you've developed any health problems from breathing in silica dust. Your doctor may prescribe any number of the following tests to evaluate potential damage from silica dust:

- Physical exam

- Breathing tests

- Chest x-ray

- CT scan

- Bronchoscopy

- Mucus (sputum) evaluation

- Lung biopsy

What is Silicosis?

Silicosis is a debilitating and often fatal lung disease caused by exposure to silica dust. When silica dust is inhaled, the particles can damage the lungs, causing scarring and swelling. This can lead to difficulty breathing and other major side effects. Additionally, someone with silicosis is more likely to develop other serious health conditions, such as tuberculosis and COPD.

There is no cure for silicosis. However, there are prescription drugs that may help alleviate silicosis symptoms. For more serious cases, a lung transplant may be advised.

Who Is at Risk?

Anyone exposed to breathable silica dust is at risk; however, a person's risk increases as the level of exposure or time of exposure increases. Someone who works around silica dust daily, such as a miner or construction worker, will have a high risk of developing silicosis if the proper safety precautions are not in place on the work site.

However, family members of individuals who work around silica dust can be at risk too. If a miner comes home from the work site covered in silica dust, they could inadvertently expose their family to the toxic dust. Additionally, someone who lives near a mine or quarry where silica dust is released into the air could be at risk for silicosis or another silica-related disease.

Types of Silicosis

There are three different types of silicosis based on the severity of the exposure.

Chronic silicosis - Occurs after 10 or more years of exposure at low levels. Chronic silicosis is the most common silicosis diagnosis and often goes undetected for years.

Accelerated silicosis - Occurs after 5 to 10 years of exposure at higher levels of silica dust.

Acute silicosis - Occurs weeks or months after exposure to extremely high levels of silica dust. Death, in these cases, can occur within a matter of months.

- Shortness of breath

- Severe cough

- Possible fever

- Weakness

- Fatigue

- Loss of appetite

- Chest pain

- Lung scarring

- Inflammation

- Fluid in the lungs

- Weight loss

- Respiratory failure

- Death

Silica Exposure Lawsuits

Who Qualifies for a Silica Lawsuit?

Anyone exposed to silica dust or silica sand who has been diagnosed with silicosis or another silica disease may be eligible to file a lawsuit.

Who Can Be Sued for Silicosis?

Depending on the nature and conditions of silica exposure, individuals may be able to sue one or more of the following:

- Manufacturers

Individuals suffering from silicosis as a result of faulty tools, materials or safety equipment may be able to file a product liability claim. In this type of lawsuit, the individual would sue the equipment manufacturer for breach of warranty, defective product design or negligence.

- Negligent Employers

If a manager instructed an employee to work in unsafe environmental conditions or without safety equipment, exposing the employee to silica dust, the employee may be able to obtain legal damages from their employer.

Silicosis Lawsuit Compensation

There have been no silicosis settlements or verdicts in the last decade. Compensation from a silica lawsuit can be approximated based on other lawsuits that deal with toxic exposure. Depending on the circumstances, a plaintiff may choose to seek compensatory damages for any of the following reasons:

- A plaintiff may seek damages to cover the cost of medical expenses.

- A plaintiff may seek damages to cover lost wages or employee benefits.

- A plaintiff may seek damages to cover loss of consortium.

- A plaintiff may seek damages to cover pain and suffering endured from toxic exposure and related health conditions.

In addition to compensatory damages, a plaintiff filing a silicosis lawsuit may choose to seek punitive damages to financially punish an employer or manufacturer who failed to disclose the health risks associated with silica dust.

Silica Litigation History

Regulators have been aware of the dangers of silica dust exposure since at least the 1930s. Since then, the United States has experienced several waves of silica and silicosis litigation as a result of the evolving understanding of exposure routes and dangers.

Pre-Hawk's Nest Litigation | Early 1930s

In the 1930s, national awareness of silicosis increased, creating an influx of silica exposure lawsuits. Silicosis patients and families of employees who died of silicosis filed suit and received large settlements from suppliers and employers in dusty trades.

During this time period, insurers covering silica-using companies found themselves inundated with lawsuits and claims.

The lawsuits became such a burden that insurers began lobbying for silicosis coverage under workers' compensation. They hoped to offset the burden of silica litigation and settlements by providing compulsory--but limited--coverage through workers' compensation.

The Hawk's Nest Disaster | 1931-1936

On the heels of the first wave of silica litigation in the 1930s, an industrial disaster raised the silicosis profile even higher.

In the mid 1930s, The Union Carbide Corporation wanted to drill a tunnel through Hawk's Nest Mountain in West Virginia. According to company records, 2,000 employees worked on this project with little to no safety equipment to protect their lungs.

Union Carbide knew the mountain was made of pure silica and that drilling silica posed grave health risks to employees in the area.

700 laborers died while drilling the tunnel, and Union Carbide buried them in unmarked graves on the side of the road. As a result, 538 workers--or their families--filed lawsuits against Union Carbide.

By the end of 1937, 46 states had passed silicosis safety laws, many of which provided workers' compensation coverage for silica-related workplace injuries.

The Oil Boom and Silicosis | The 1970s-2000s

According to one expert, business and environmental safety experts declared silicosis a problem of the past by the 1950s. As a result, public awareness of the dangers of silica decreased.

Simultaneously, new industries began employing hundreds of thousands of workers in silica-heavy occupations. Shipyards, oil rigs and oil refineries all dedicated personnel to countless hours of sandblasting.

Sandblasters become the second wave of silica lawsuits in the 1970s-2000s.

Throughout the 1970s, several regulatory bodies began enacting and tightening regulations in order to protect workers from the dangers of breathing silica dust.

Silica and Silicosis Lawsuit News

November 2019 | NPR Reports Silicosis in the Countertop Industry

National Public Radio reported on Ublester Rodriguez. Rodriguez worked in the countertop industry for years. In the early years, he and his colleagues dry-cut the stone slabs in their workshop.

The company, Stone Systems, later changed this practice. But for Rodriguez, the damage was already done. He is the first known case of silicosis in the modern countertop fabrication industry.

Silicosis has negatively impacted Rodriguez in a number of ways. He no longer plays soccer and has been told he will soon need a lung transplant. He is currently suing Stone Systems for causing his illness.

May 2020 | Anti-Science "Experts" Outed by Former OSHA Leader

David Michaels served as Assistant Secretary of Labor for the Occupational Safety and Health Administration (OSHA) from 2009 - 2017. During his tenure, Michaels encountered a number of "expert" consultants. The consultants' opinions often supported industry or big business.

In an interview with Vox, Michaels mentioned several industries affected by these consultants. The countertop industry was among them. He recounted a meeting with one such consultant, Dr. Tony Cox, at a silica hearing. Dr. Cox claimed OSHA had not proved silica causes silicosis. OSHA ignored his comments because they were "so ludicrous."

People like David Michaels can see the absurd nature of Dr. Cox's claims. But, such misinformation can still confuse a lot of people. According to Michaels, the confusion is the point. It muddles the information, making it more difficult to impose effective safety regulations.

Silica Regulations

The Occupational Health and Safety Administration (OSHA) ensures safe working conditions for all workers in the United States, including those working in silica-laden conditions. OSHA has separate silica standards for construction and general industry/maritime employers.

Because silicosis has no cure, all related regulations aim to prevent the disease.

Current OSHA Regulations

According to OSHA standards, construction employers must:

- Create and use a plan to identify tasks involving silica exposure, protect employees from silica and keep unprotected individuals out of high-exposure areas.

- Offer medical exams, including chest x-rays and lung-function tests, to all workers required to wear a respirator for 30 days or more per year.

- Train workers to limit silica exposure.

- Record all exposure measurements, data and associated medical exams.

In addition to the requirements for construction employers, general industry and maritime employers must also:

- Measure employee silica exposure if exposure will be at or above OSHA's daily exposure cutoff level.

- Protect employees from exposures higher than the daily exposure cutoff.

- Provide respirators to employees exposed to levels of silica dust above OSHA's daily cutoff level.

Current OSHA standards went into effect in 2018 and created upheaval in silica-heavy industries. Employers in the space protested the reduction of OSHA's daily exposure cutoff level (to its current state), claiming it was unnecessary and cost prohibitive.

For more information on OSHA's silica regulations, you can visit the OSHA Crystalline Silica page.

Despite OSHA's current silica regulations, in October 2019, NPR published an article identifying 18 workers in four states who were recently diagnosed with silicosis after working with "engineered stone" -- a material that can contain up to 90% silica. This article addressed the current silica-related health conditions that workers face in the artificial stone industry and the pending legislative actions attempting to rectify the issue.

Silica Litigation and Legislative Timeline

Silica regulation and litigation have been steadily evolving since the early 20th century. The most consequential events in that evolution are included in the timeline below.

1930s: The first wave of silica lawsuits occurs, and insurance companies lobby for workers' compensation coverage of silicosis.

1936: The Hawk's Nest disaster claims more than 700 lives. 536 employees--or their surviving family members--sue Union Carbide over their lung diseases.

1974: The National Institute for Occupational Safety and Health (NIOSH) recommends decreasing federal silica exposure limits by half.

1994: OSHA names silica rulemaking a priority.

1995: OSHA again names silica rulemaking a priority.

1996: U.S.Secretary of Labor launches "It's Not Just Dust" campaign to raise awareness of silicosis and promote silica safety in the workplace.

OSHA, NIOSH and the American Lung Association host "The Campaign to End Silicosis."

OSHA adds silica to its regulatory agenda and drafts a silica standard.

The World Health Organization's (WHO's) International Agency on Cancer Research (IARC) classifies silica as a known human carcinogen.

1997: Silica appears on OSHA's regulatory agenda.

1998: OSHA creates a Silica Work Group within its Committee on Construction Safety and Health.

1999-2000: OSHA hosts multiple silica stakeholder meetings.

2003: OSHA asks the Small Business Regulatory Fairness Enforcement Act panel to review a proposed silica standard.

2005: Federal Judge Janis Graham Jack dismisses thousands of silica lawsuits after discovering fraudulent elements tying them all together.

2011: OSHA sends silica standard draft to the U.S. Office of Management and Budget (OMB) for review of "economically significant" rules.

2012: The U.S. Senate's Committee on Health, Education, Labor & Pensions meets to address delays in the silica regulatory process.

2013: OMB returns the proposed silica standard to OSHA, and OSHA releases a press release announcing the impending new standard.

2014: OSHA hosts weeks of public hearings to gather responses to the proposed silica standard.

2015: OSHA submits the final silica standard to OMB for review.

OSHA issues a Hazard Alert regarding silica exposure in the natural and manufactured stone countertop industries.

2016: OSHA issues its final rule, establishing multiple safety standards for airborne crystalline silica.

Multiple silica-related organizations sue the federal government to stop enforcement of OSHA's final rule, claiming it is unnecessary and costly.

2017: Enforcement of the silica standard in the construction industry begins.

The final rule does not apply to coal mining.

The U.S. Court of Appeals for the District of Columbia Circuit rejects all remaining industry-filed suits challenging OSHA's final rule.

2018: Enforcement of the silica standard for general and maritime industry begins.

NPR reports 2,000 cases of advanced black lung in Appalachian coal miners.

The Mine Safety and Health Administration (MSHA) lists silica as a long-term action item for metal/nonmetal mines, not coal mines.

The past few years have brought awareness to an old occupational health risk appearing in a modern industry. Workers who manipulate "engineered stone" countertops are falling ill with a disease known as silicosis. Silicosis is a potentially deadly disease that takes the lives of 100 American workers each year. As concern and awareness grow around the safety of handling "engineered stone," many workers who frequently work with materials containing silica are filing silica dust exposure lawsuits.

The past few years have brought awareness to an old occupational health risk appearing in a modern industry. Workers who manipulate "engineered stone" countertops are falling ill with a disease known as silicosis. Silicosis is a potentially deadly disease that takes the lives of 100 American workers each year. As concern and awareness grow around the safety of handling "engineered stone," many workers who frequently work with materials containing silica are filing silica dust exposure lawsuits.